SkyTrain type technology clearly a winner in Japan

Have you ever noticed why the tracks on the Vancouver SkyTrain look different from the tracks that you might find in other rapid transit systems around the world? Specifically, we refer to this:

Earlier today some of our contributors were discussing about train lines in Japan, and came across a document that had to do with one of Osaka’s newest subway lines. The document prominently features discussion on Linear Induction Motor technology, which is a component of the technologies used by some Vancouver SkyTrain lines. Rapid transit lines using linear induction motor technology can be characterized by the use of a “fourth rail”, which is an aluminum strip that acts as a reaction rail; it is placed in between the two tracks. While the rail is an important component of this technology, what the technology really has to do with is the method of propulsion for train cars.

The new line in Osaka is actually fundamentally no different from an implementation of SkyTrain, making use of both Linear Induction Motor technology as well as (after 1996) Automatic Train Control – two defining points of SkyTrain lines using Bombardier’s Innovia ART technology (i.e. the Expo Line, Millennium Line and upcoming Evergreen Line), although the line is fully underground and the particular designs for the technology implementation and rolling stock were brought forward by a different company.

This is probably why a majority of LIM lines with automatic train control around the world are overlooked; it is often forgotten that there are competing companies that offer implementations of rapid transit with specifications similar to or no different fundamentally than Bombardier’s Innovia ART – which was built upon the former ICTS (Intermediate Capacity Transit System) that pioneered the combination of linear-induction motor technology and automatic train control technology.

Linear Induction Motor (LIM) technology, as we have explained before, is an alternative technology for rail propulsion in that the rotor inside the propulsion engine is rolled out as a “fourth rail” or “reaction rail” in between the two steel tracks that secure the wheels and the bogie; propulsion for trains comes directly from the magnetic reaction between these two rails and not from the turning of the wheels. This can allow for a reduction in engine size and thus allow train platforms to be much closer to the ground level.

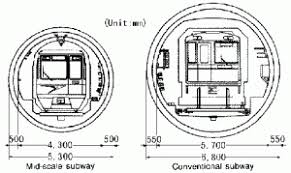

LIM technology came under the spotlight in Osaka, Japan in the early to mid 1980s, around the same time that the Vancouver SkyTrain utilizing the ICTS technology (which pioneered the use of LIM) was being tested and constructed. The commissioned “Investigative Committee for Miniaturization of Subway” was working as early as 1979, searching for new ways to improve the cost-efficiency of expensive subway construction, with as little effect as possible on passenger comfort. The committee ran a series of tests that compared such a tehcnology to existing rotary motor technology (which had been the standard in rapid transit systems for several years by then) and found benefits in LIM technology that could apply to the construction of an upcoming subway line in Osaka.

Osaka was pursuing LIM for this main purpose and benefit: a significantly smaller footprint. LIM allowed for a vehicle height reduction that was fundamental in that it also allowed subway tunnels to be much smaller, thus contributing to a reduction in capital costs for such subway systems (of approximately 20%). It allowed for a reduction in vehicle height that did not sacrifice passenger comfort (i.e. lowering of floor height, not ceiling height).

LIM technology has several other proven benefits, many of these benefits allowing for such a technology to apply so well in Vancouver. Many LIM benefits are made clear in recent documentation for Bombardier’s newest Innovia ART 300 cars [CLICK HERE to view document][62]; the new generation of ART is now provided in both an LIM propulsion and rotary propulsion option but Bombardier has made the benefits of LIM Propulsion technology very clear.

Trains using LIMs are significantly lighter, which helps at reducing the load on elevated guideways. The majority of the Vancouver SkyTrain operates successfully on low-profile elevated guide-ways. Other design attributes such as the ability to handle steeper grades and smaller curve radii allow LIM-based ART systems to operate in demanding and challenging alignments for minimized civil cost over other alternatives.

Because the motor itself was designed in such a way so that the magnetic reactions assist not only in propulsion/speed up of trains but also in slowing down the train (i.e. braking) by offering reverse thrust, regular wheel-contact brakes not need be used as often – this can reduce vehicle maintenance costs.

LIM allows rail systems to overcome several other problems that are a result of a technology that has fundamentally remained unchanged for the last one hundred years – for example, adhesion between the wheel and rail.

LIM allows trains to navigate tight curves (tighter than on most traditional systems) without making any additional noise (as can be evident on most conventional rail systems with electric motors) and without any need for a significant reduction in speed. No gear box is attached to the wheel sets which allow each two wheels (per side) to “steer themselves”, or turn on their own along with the rail, reducing stress on both the wheels and the rail and providing passengers with a quieter, more comfortable experience.

LIMs (Linear Induction Motors) are also designed to be optimized for faster acceleration [37], which can reduce total station layover times. When combined with automatic train control technology, LIM’s advantages complement that of ATC, allowing trains to run very frequently, very safely. The Vancouver SkyTrain’s Expo amd Millennium Line segments, which were the pioneering establishment of LIM technology with ATC, can be modified so as to operate as frequently as every 75 seconds – and in fact it was operating so frequently during the 2010 Winter Olympics without a single issue.

LIM technology makes a significant contribution in SkyTrain’s ability to operate very frequently. Faster acceleration and the reduction or removal of major slowdown requirements on curve sections contributes to the system speed capabilities: the Expo and Millennium Lines are the fastest rapid transit lines in Canada with an average travel speed (counting stops) of approximately 45km/h.

Clearly, this combination of technologies is the way of the future for the operation of efficient, cost-effective rapid transit. New lines are being built with LIM technology all over Japan. The next Osaka Subway Line was built with the same technology and additional cities including Tokyo (which is the largest city in Japan and in which operates one of the world’s largest rapid transit rail systems) Kobe City, Yokohama City, Fukuoka City and others are pursuing or have pursued LIM propulsion technology.

Japan has been known for being a trend-setter and a role model in the implementations of new technologies; not surprisingly, the rest of the world should has plenty of reason to definitely be following the examples in Japan such as those in Osaka for the implementation of rail rapid transit systems.

“Although Osaka is the oldest city in Japan, the forward-looking and enterprising spirit of its people allowed Osaka to transform itself dramatically at each historical turning point, and to play a leading role in the development of Japan’s city planning, industry, and culture with keeping Osaka’s rich historical heritage.”

About SkyTrain for Surrey

SkyTrain for Surrey is the community organization that advocated for the Surrey-Langley SkyTrain extension (SLS). From our beginnings as a petition calling for the scrapping of a street-level LRT proposal, we grew into a community of like-minded folk, taking on various projects such as making SkyTrain an election issue in 2018 as a registered advocacy group. Today we are pushing for the construction of the SLS as well as the King George SkyTrain extension (KGS).

Media Contact:

Daryl Dela Cruz – Founder, SkyTrain for Surrey

Phone: +1 604 329 3529, [email protected]